WARNING : Drilling, sawing, sanding or machining wood products can expose you to wood dust, a substance known to the State of California to cause cancer; Avoid inhaling wood dust or use a dust mask or other safeguards for personal protection. For more information go to www.P65Warnings.ca.gov/wood.

WARNING: This product can expose you to chemicals including nickel and lead, which are known to the State of California to cause cancer and lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

![[0, ]](images/warning.png) California Proposition 65

California Proposition 65

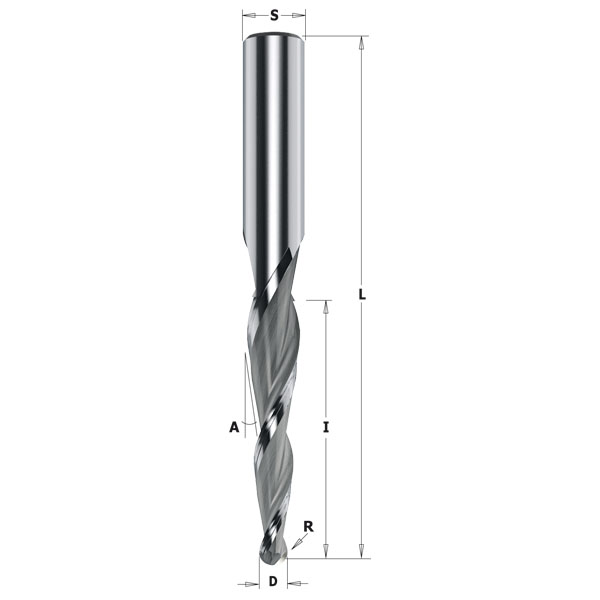

Solid Carbide Upcut 2D/3D Carving Tapered Ball Nose Spiral Bits

152

Technical details:

• Premium quality HWM.

• Upcut spiral cutting edges [Z2/Z3].

• Excellent finish on the lower side of the work piece.

• Upward chip ejection.

Application:

specially designed for 2D and 3D CNC profiling and carving in plastic, aluminum & wood for several uses like:

• A perfect bit for 3D carving

• Precision 2D and 3D large scale carving

• Great for deep profiling

• Dimensional signage

• 3D millwork

• 2D and 3D contouring, profiling, modeling and pattern making for cabinetry, sign making, furniture making and jewelry mold making

• Perfect for model-makers on large 3D milling profiles in abrasive EPS foam and other materials.

• Ideal on aluminum, plastic and wood-based materials.

Excellent for cutting:

• Acrylonitrile-Butadiene-Styrene (ABS)

• Acrylic

• Acrylic Stone

• Aluminum

• Brass

• Bronze

• Composite

• Copper

• CORIAN®

• COROPLAST®

• DIBOND®

• ETHAFOAM®

• Ethylene-vinyl Acetate Foam (EVA)

• Expanded Polypropylene (EPP)

• Expanded Polystyrene Foam (EPS)

• Extruded Polystyrene Foam (XPS)

• Fiberglass

• Fiberglass PCB Board

• Foam Board

• Graphite

• HDPE

• HDU

• 20lbs High Density Urethane

• LEXAN®

• MDF/HDF

• PALFOAM™

• Phenolics

• Phenolic Composites

• Plastics

• Poly (methyl methacrylate) (PMMA)

• Polyethylene Foam

• POLYLAM®

• Polyurethane Foam

• PVC

• PVC Foam Board

• Sign Board

• Sign Foam

• Titanium

• Tooling Board

• Wood

• XPE (Cross Linked Polyethylene) Foam

Tips for Milling Plastics:

• pay attention to heat input.

• pay attention to chip-loads when using small diameters.

• use air-blast to keep chip away and cooling the tool.